About Our factory

download.PDF- Ganpati Enclave , Bhagwanpur, Uttarakhand - 249402

- (+91) 9045464728

ravinderpal4728@gmail.com

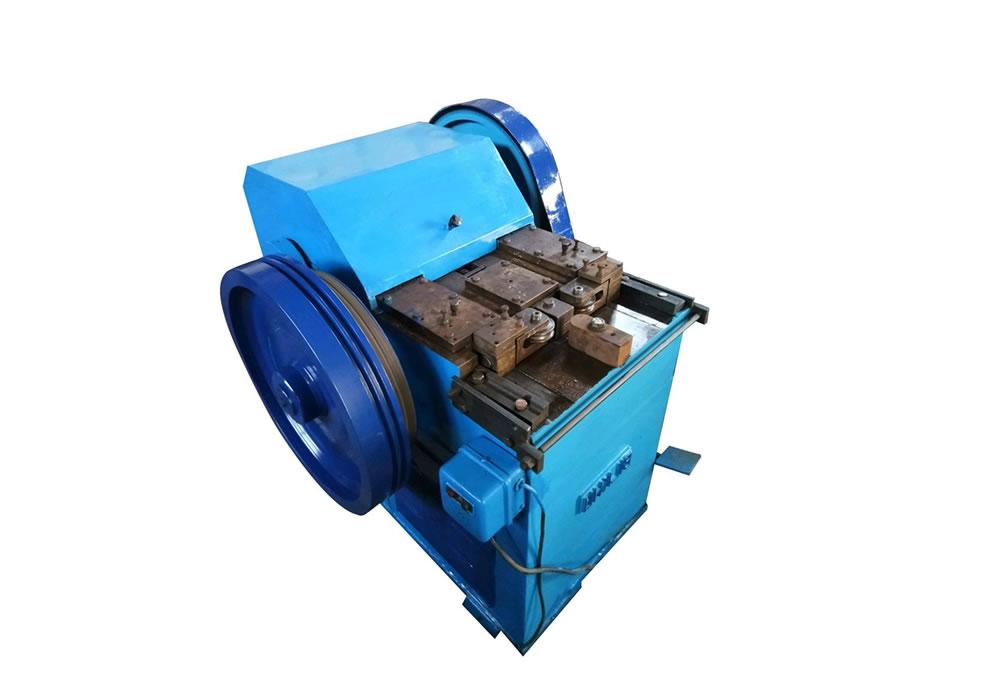

Pipe/Bolt Bending Machine

Pipe/Bolt Bending Machine

The quality machines for tube industry. Thorson Tube & Pipe bending machines can be used for economical, small batch to high volume mass production. The range includes Motorised, PLC base Single Axis, Two Axis & CNC 3 Axis Tube & Pipe Bending Machines. The machine has all production related features. We also supply tooling for the simple to most complex tube & Pipe bending applications.

There are four important forces acting on each of the die segments during the threading operation. The direction of the forces are; (a) axially along the material, (b) radially outward from the material, (c) radially inward toward the material, and (d) tangential to the material in the direction of rotation of the material. Each of these forces must be controlled by the geometry of the dies and the design of the die head.

The move which is built into the die segments allows the cutting segment to "find" the groove which has been started by the previous segment and to take a deeper cut in the same groove. Move is built into the die segments at the factory and will not change during use or in subsequent grinding. This is also true of the helix angle. The helix angle required is based on the pitch and the diameter of the thread. As long as the move of segment is correct, the helix angle may be allowed to vary somewhat without serious results.

This is what allows some dies to be used to thread more than one diameter of material. There are limits to the range of diameters that can be threaded by each die set. The range of diameters that can be threaded depends on the size of the material. In general, smaller diameters have a smaller range than larger diameters.